Case Study 6: Umeda Center Building

Quick and Quality replacement for aged air conditioning system

Umeda Center Building in Osaka, Japan was awarded the very first “SHASE Special Award - Renewal Award” in 2013, an award to help promote the development of renovation technology, that is to keep building equipment sustainable in a long term. Thanks to the improvement of office environment, occupation ratio has been kept at a high level through the years.

*SHASE:

The society of Heating, Air-Conditioning and Sanitary Engineers of Japan

BACKGROUND

- Aging equipment(20 years in use)

- To cope with increasing cooling load

- To minimize tenant fee loss during replacement

- Not to disturb tenant's working hours

- To organize well managed construction schedule due to a fully occupied building

Daikin Solution

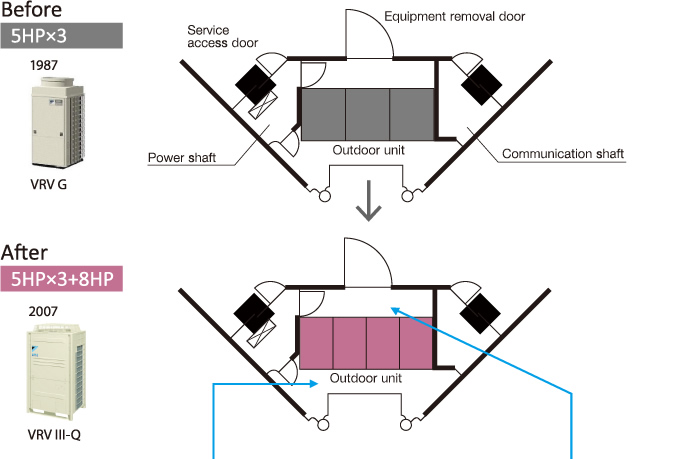

- Increased capacity from 60HP to 86HP within same installation space

- Construction done only on weekends not to disturb tenants by the noise and vibration of construction (8days per floor)

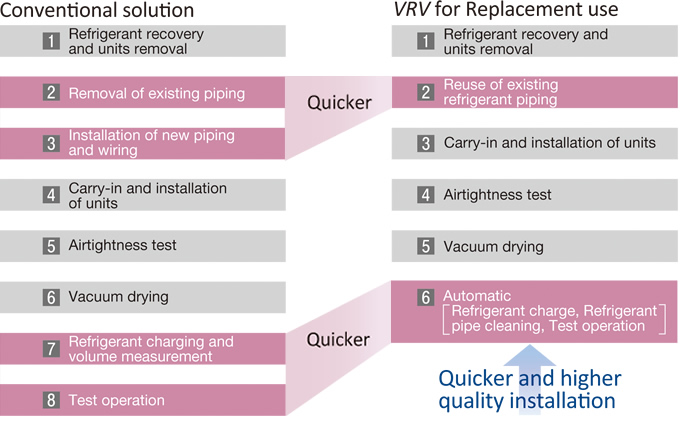

- Shortened the construction period by the reuse of existing piping , automatic cleaning and automatic refrigerant charge

Daikin Products and Services

- About 420 outdoor units

DAIKIN Advantages

1.TIME SAVING

Enables smooth replacement of air conditioning with less effect on operations and users in the building with the simple use of existing refrigerant piping. In the past, special equipment and work was needed to clean pipes when using existing piping, but this is no longer required. A new function automatically deals with contamination inside piping during refrigerant charging, eliminating the work involved in cleaning. Even applicable for non-DAIKIN systems!

*For reuse of existing refrigerant piping, it is possible to use piping or branched piping capable of handling 3.3 MPa or more.

Heat insulation is necessary for liquid piping and gas piping.

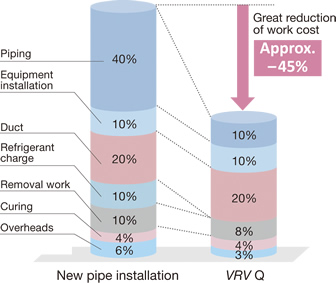

2.Cost saving

Work costs for pipe removal, installation and insulation account for almost 80% of the total cost. By the reuse of existing piping, 45% of cost down can be realized compared to installing new pipes.

On top of the benefits from reusing pipes, costs of charging refrigerant to clean the pipes are also saved.

3.Space saving

Smaller footprint, less installation space

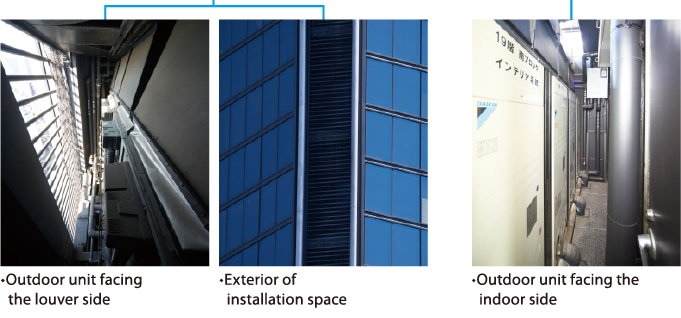

Outdoor units are installed in the corners of each floor.

Maintenance space can be accessed from the door on the side.

The louver side is painted black to make the outdoor unit unnoticed from outside

4.Easy Installation

Easy to carry in

Compact size

5.Automatic

Refrigerant charging, cleaning and test operation done with just a single switch.

The unique automatic refrigerant charge eliminates the need to calculate refrigerant volume and ensures that the system will operate perfectly. Not knowing the exact piping lengths because of changes or mistakes in case you didn't do the original installation or replacing a competitor installation no longer poses a problem. Furthermore, there is no need to clean inside piping as this is handled automatically by the VRV Q unit.

Building Information

Umeda Center Building

| Application | Office |

|---|---|

| Location | Osaka, Japan |

| Year of Completion | 1987 |

| Year of Renovation | 2007-2009 |